mechanical tools names and pictures pdf

Mechanical tools are essential for various industries, offering versatility and efficiency․ They empower professionals and DIYers to achieve precision and safety in their work․

1․1 Overview of Mechanical Tools

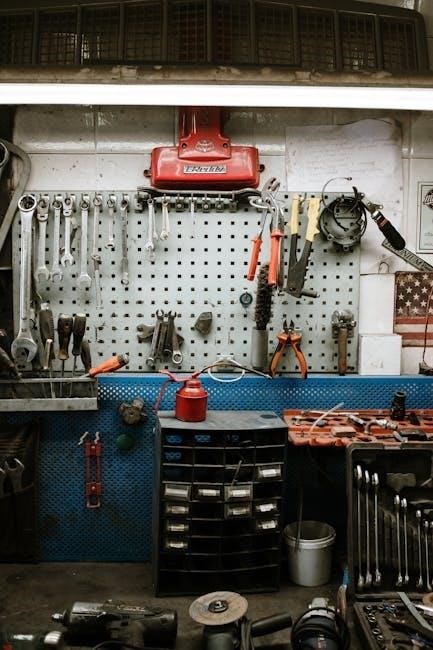

Mechanical tools are devices used to accomplish tasks requiring force, precision, or repetition․ They range from simple hand tools like wrenches and pliers to complex power tools such as drills and grinders․ These tools are essential for industries like automotive, construction, and manufacturing․ Hand tools enable manual operations, while power tools enhance efficiency and speed․ Understanding their names and functions is crucial for effective use․ Tools like screwdrivers, hammers, and tape measures are fundamental for everyday tasks․ These tools are categorized based on their applications, ensuring versatility and adaptability across various projects․ Their proper use ensures safety and productivity, making them indispensable in both professional and DIY settings․

1․2 Importance of Knowing Tool Names and Uses

Understanding mechanical tool names and their applications is vital for efficiency and safety․ Correct tool identification prevents damage to equipment and ensures tasks are completed effectively․ Misusing tools can lead to accidents or project failures․ Knowing tool functions enhances problem-solving skills and workflow․ It also aids in selecting the right tool for specific tasks, reducing time and effort․ For professionals and DIY enthusiasts, this knowledge is a foundation for mastering mechanical skills․ Proper tool usage extends equipment lifespan and improves overall productivity, making it an essential skill in any mechanical or engineering setting․ It fosters confidence and competence in handling various projects․

Common Hand Tools in Mechanical Work

Hand tools like wrenches, pliers, screwdrivers, and hammers are fundamental for mechanical tasks․ They offer versatility and precision, enabling efficient problem-solving and project execution in various settings․

2․1 Wrenches and Their Uses

Wrenches are essential tools in mechanical work, offering versatility for various tasks․ Combination wrenches, available in multiple sizes, are ideal for bolts and nuts․ A breaker bar, stronger than a ratchet, is used for loosening stubborn bolts․ Adjustable wrenches allow for different bolt sizes, while impact wrenches provide high torque for tough jobs․ Organized in a toolkit by size, wrenches are indispensable for tightening, loosening, and holding objects securely․ Their durability and precision make them a must-have for any mechanical task, ensuring efficiency and safety in workshops and projects․

2․2 Pliers and Their Applications

Pliers are versatile hand tools used for gripping, bending, and shaping objects․ Needle-nose pliers are ideal for reaching small spaces, while slip-joint pliers excel at gripping various objects․ Locking pliers securely hold items in place, making them perfect for welding and repairs․ Lineman’s pliers are designed for cutting and twisting wires, while tong pliers are used for heavy-duty tasks․ Specialized pliers, like bent-nose and flat-nose, cater to specific needs․ Their ergonomic designs ensure comfort and control․ Pliers are indispensable in mechanical work, offering precise grip and versatility for numerous applications, making them a must-have in any toolkit for professionals and DIY enthusiasts alike․

2․3 Screwdrivers: Types and Functions

Screwdrivers are essential tools for driving screws and other fasteners․ They come in various types, each designed for specific tasks․ Flathead screwdrivers are used for slotted screws, while Phillips-head screwdrivers handle cross-shaped screws․ Torx screwdrivers are ideal for star-shaped screws, commonly found in electronics․ Allen wrench screwdrivers, or hex keys, are used for bolts with hexagonal sockets․ Insulated screwdrivers are designed for electrical work, offering protection against shocks․ Ratcheting screwdrivers provide ease of use with their reversible mechanism․ Precision screwdrivers are compact and perfect for small or delicate tasks․ Using the right screwdriver ensures efficiency and prevents damage to screws or tools, making them indispensable in mechanical and DIY projects․

2․4 Hammers and Mallets

Hammers and mallets are fundamental tools for delivering precise force in various mechanical tasks․ Claw hammers are ideal for driving nails and pulling them out, while ball-peen hammers are used for shaping metal and striking punches․ Sledgehammers provide immense force for heavy-duty tasks like breaking concrete․ Mallets, made of wood, plastic, or rubber, are used for tapping parts into place without causing damage․ The choice of tool depends on the material and force required․ Proper handling and selection ensure safety and efficiency in both professional and DIY projects, making hammers and mallets indispensable in any toolkit․

Power Tools in Mechanics

Power tools enhance efficiency and precision in mechanical tasks․ Drills, impact drivers, grinders, and saws are essential for cutting, shaping, and assembling materials with speed and accuracy․

3․1 Drills and Impact Drivers

Drills are versatile power tools used for creating holes in various materials like metal, wood, and plastic․ They operate at adjustable speeds, ensuring precision in different tasks․ Impact drivers, on the other hand, are designed for driving screws and bolts with high torque․ They are often used in tight spaces due to their compact design․ Both tools are indispensable in mechanical work, offering efficiency and reliability․ Proper usage requires understanding their functions and safety guidelines to avoid accidents․ Regular maintenance, such as cleaning and lubricating, extends their lifespan and performance․

3․2 Grinders and Sanders

Grinders and sanders are essential power tools for surface preparation and material removal․ Grinders, such as angle grinders, are used for cutting, grinding, and polishing metals, concrete, and stone․ Sanders, including belt sanders and orbital sanders, smoothen surfaces by removing imperfections․ Both tools enhance the quality of mechanical work, ensuring precise finishes․ Proper safety gear, like goggles and dust masks, is crucial when operating these tools․ Regular maintenance, such as replacing abrasives and checking motor performance, ensures longevity․ Their versatility makes them indispensable in workshops, construction, and automotive industries for achieving professional-grade results․

3․3 Saws and Cutting Tools

Saws and cutting tools are vital for precise material cutting in mechanical work․ Types include jigsaws, circular saws, and reciprocating saws, each designed for specific tasks․ Jigsaws excel at curved cuts in wood or metal, while circular saws are ideal for straight cuts in large materials․ Reciprocating saws, like Sawzalls, are perfect for demolition and tight spaces․ These tools enhance productivity in woodworking, construction, and automotive projects․ Safety gear, such as gloves and goggles, is essential to prevent accidents․ Regular blade maintenance ensures optimal performance and longevity․ Understanding the right saw for the job guarantees clean, accurate cuts, making them indispensable in any workshop or project setup․

Safety Equipment and PPE

Safety equipment and PPE are crucial for protecting workers from injuries․ Essential items include gloves, goggles, welding jackets, and flame retardant materials․ A downloadable PDF list provides detailed guidance;

4․1 Essential Safety Gear for Tool Usage

Protective gear is vital when using mechanical tools․ Safety gloves prevent hand injuries, while goggles shield eyes from debris․ Steel-toe boots and hard hats ensure protection in hazardous environments․ Flame-retardant materials, like welding jackets, are essential for high-heat tasks․ A comprehensive PDF guide lists these items, emphasizing their importance․ Proper PPE ensures compliance with workplace safety standards, reducing accident risks․ Always refer to a detailed safety equipment list for specific tools and tasks, ensuring optimal protection and adherence to industry regulations․ Safety should never be compromised when working with mechanical tools․

How to Create a Mechanical Tools PDF Guide

Compile a list of tools with names, pictures, and uses․ Organize content logically, include safety tips, and ensure clarity for easy reference in the PDF guide․

5․1 Steps to Compile a Comprehensive Tool List

To create a detailed mechanical tools PDF guide, start by listing all essential tools, categorizing them by type (e․g․, hand tools, power tools)․ Include high-quality images for visual identification․ Add brief descriptions of each tool’s purpose and usage tips․ Organize the content logically, using tables or charts for clarity․ Incorporate safety guidelines and PPE recommendations․ Finally, proofread the document for accuracy and ensure it is user-friendly for easy navigation․ This structured approach ensures your guide is informative and practical for professionals and DIY enthusiasts alike․

FAQs About Mechanical Tools

What are the most common mechanical tools? What tools are essential for beginners? How can I identify tools from pictures? What safety precautions are necessary when using tools?

6․1 Common Questions and Answers

Q: What are the most essential mechanical tools?

A: The most essential tools include wrenches, screwdrivers, pliers, hammers, and tape measures, which are versatile for various tasks․

Q: How can I identify tools from pictures?

A: Refer to a tool name and picture guide, which provides clear images and descriptions to help recognize each tool easily․

Q: What safety gear is necessary when using tools?

A: Safety glasses, gloves, and a dust mask are crucial to protect against debris and ensure safe tool usage․

Q: Are power tools better than hand tools?

A: It depends on the task; power tools offer speed for heavy-duty work, while hand tools provide precision for smaller projects․